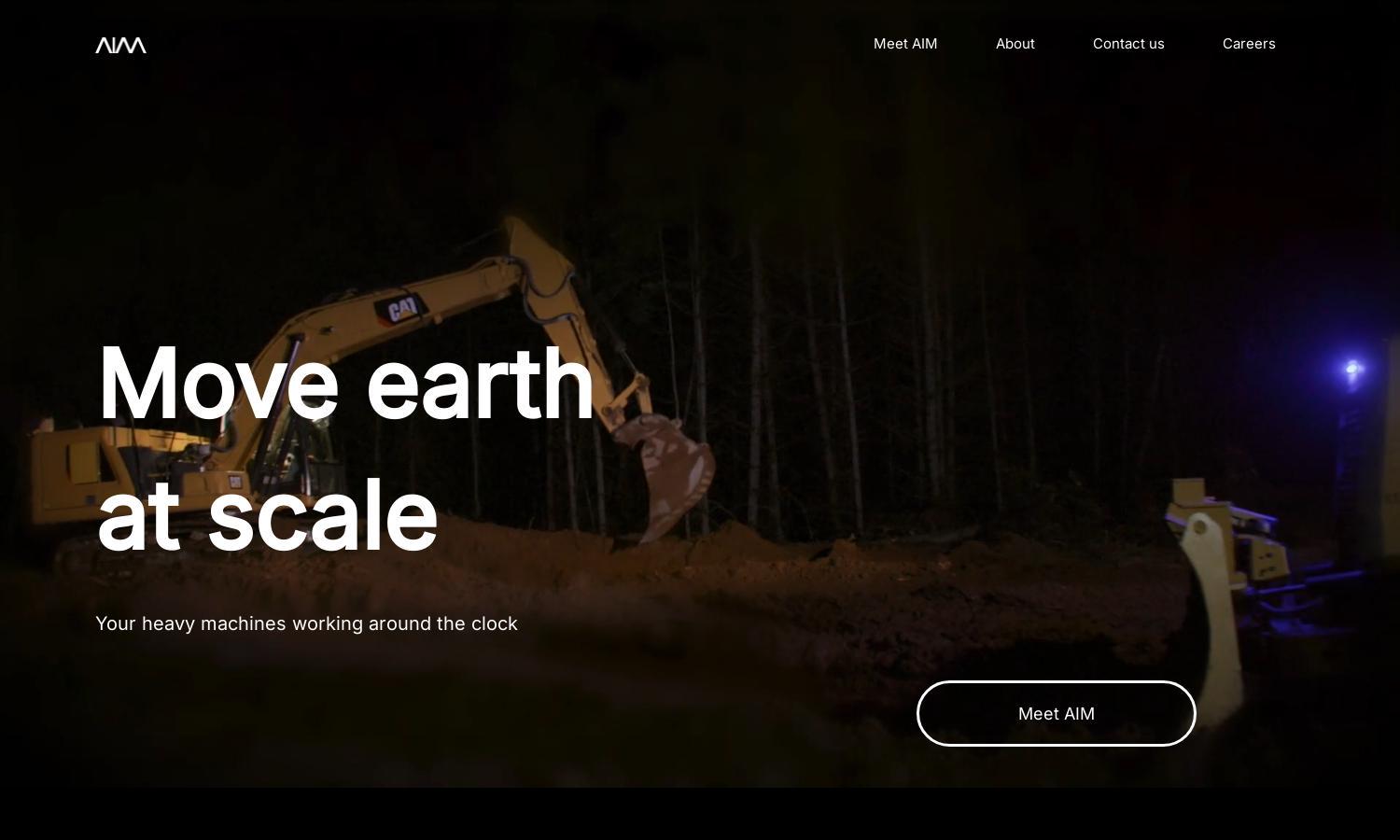

AIM Intelligent Machines

About AIM Intelligent Machines

AIM Intelligent Machines redefines heavy machinery operations, enabling autonomous functionality in earthmoving equipment. With a focus on safety and enhanced productivity, AIM retrofits machines to operate without operators, allowing for year-round utilization. This innovative approach not only protects workers but also fosters upskilling opportunities, making AIM essential in construction and mining.

AIM Intelligent Machines offers a customizable consultation for businesses looking to upgrade their heavy machinery. Pricing plans vary based on equipment and integration complexity, ensuring value at each tier. Upgrading enhances safety and operational efficiency, making substantial impacts in construction and mining sectors while addressing the unique needs of various clients.

The user interface of AIM Intelligent Machines is designed for seamless navigation and efficient workflow. Its intuitive layout allows users to easily manage and monitor autonomous operations while providing access to key features. The focus on user experience ensures that all operators can quickly adapt and optimize their heavy machinery management at AIM.

How AIM Intelligent Machines works

Users interact with AIM Intelligent Machines by first booking a consultation to evaluate their existing heavy equipment. During onboarding, teams assess the machinery for retrofitting with AIM's cutting-edge autonomous system. Once integrated, operators manage machines from a user-friendly interface, accessing real-time data, safety protocols, and operational analytics to enhance productivity without sacrificing safety.

Key Features for AIM Intelligent Machines

Autonomous Retrofitting

AIM Intelligent Machines uniquely offers autonomous retrofitting of existing heavy equipment, enabling seamless integration of cutting-edge AI technology. This innovative feature maximizes operational efficiency, ensuring that machines can operate safely without human intervention, allowing businesses to focus on productivity and growth.

360-Degree Safety System

The advanced 360-degree safety system by AIM Intelligent Machines is designed to protect ground staff and prevent accidents during autonomous operations. This unique feature establishes multiple safety layers, ensuring that no personnel are exposed to hazardous environments, enhancing overall site safety significantly.

Upskilling Opportunities

AIM Intelligent Machines provides valuable upskilling opportunities for teams by enabling employees to transition from traditional roles to advanced site management and analytical tasks. This feature not only empowers the workforce but also enhances operational efficiency by leveraging modern technology and integrating skilled personnel into advanced areas of expertise.

You may also like: